Print on Demand or Traditional Inventory: Which Fits Your Store?

Choosing between the Print on Demand vs Traditional Inventory Model can feel overwhelming. Each model has its strengths, but it all comes down to what works best for your business. Print on demand stands out for its flexibility and scalability. It’s also a low-risk option since you only pay for products after they sell, avoiding unsold stock. On the other hand, the traditional inventory model offers higher profit potential if you’re ready to invest upfront. So, which one fits your store?

Understanding Print on Demand

How Print on Demand Works

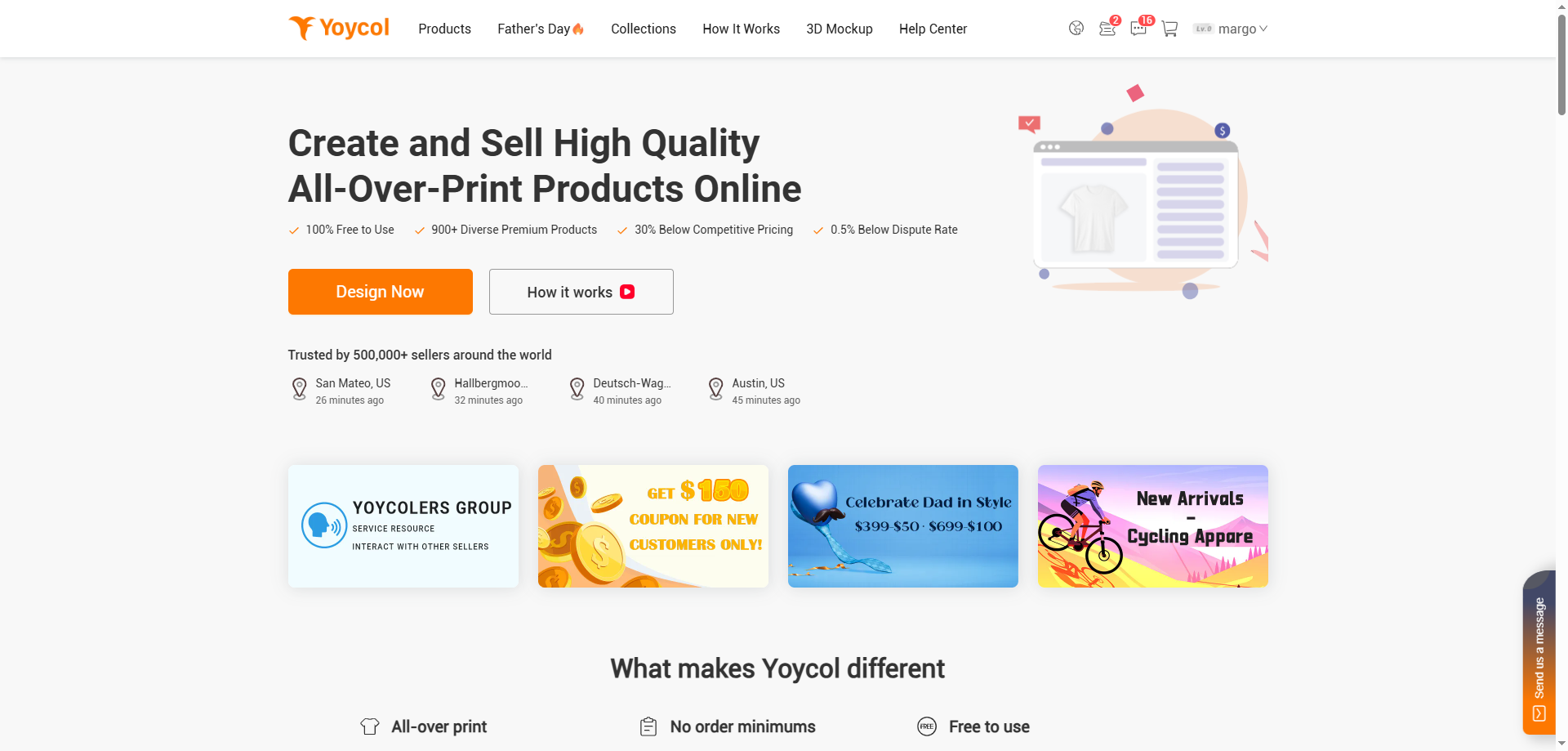

Print on demand lets you sell 1000+ products without inventory. With Yoycol's proven system: When customers order from your store, their network instantly prints and ships items globally. You only focus on designing – zero stock management or upfront costs required.

Yoycol's free mockup generator simplifies product showcasing:

Upload designs easily

Auto-apply realistic shadows/lighting with AI

Download print-ready images for Shopify/eBay listings

Real-time sync with their production system

Benefits of Print on Demand

Print on demand has many perks for new businesses. Here are some:

Low Risk: You don’t buy stock upfront. You only pay after items sell, lowering money risks.

Cost-Effective Startup: Starting costs are lower since you don’t buy bulk products.

Scalability: As sales grow, you can handle more orders without worrying about storage space.

Easy Customization: You can make personalized products for customers. About 36% of shoppers want custom items, and many will wait longer for them.

Product Variety: You can try selling different items like clothes, mugs, or home decor without buying large amounts.

The print on demand market is growing fast, with a yearly growth rate of 27.8%. In 2023, it was worth $5.04 billion and could reach $11.11 billion by 2026. This shows how popular this model is becoming.

Drawbacks of Print on Demand

Though print on demand has benefits, it also has downsides. Here are some:

Lower Profit Margins: Each item costs more than bulk production. Fees from online platforms can also reduce profits.

Limited Control Over Quality: Suppliers make the products, so you can’t fully control quality. Bad quality can upset customers.

Longer Shipping Times: Items are made after orders, which can slow delivery. Customers may get annoyed by delays.

Customer Service Challenges: Returns and complaints can be harder to manage when suppliers are involved.

Even with these issues, print on demand is still a great choice for flexible and custom stores. Picking the right platform and setting clear customer expectations can help you succeed.

Exploring the Traditional Inventory Model

How the Traditional Inventory Model Works

The traditional inventory model means buying products in large amounts. You store these items until they are sold. You manage everything, from getting products to keeping them safe. This requires a warehouse, tools to track stock, and a plan for unsold items.

Here’s how it works: You buy products ahead of time, usually at a lower price. Then, you keep them in your storage space. When someone orders, you send the product directly from your stock. This lets you check the quality of items before customers get them.

Unlike print on demand, this model needs more money and planning upfront. But it gives you full control over the types and quality of products you sell.

Benefits of the Traditional Inventory Model

The traditional inventory model has many benefits for growing businesses:

Higher Profit Margins: Buying in bulk makes each item cheaper, boosting profits.

Faster Shipping: Products are ready to ship quickly, making customers happy.

Control Over Quality: You can check items to ensure they are high quality.

Branding Opportunities: You can design special packaging for a unique experience.

Product Variety: You can offer many products to meet customer needs.

This model is great for businesses with steady sales and enough money to handle stock.

Drawbacks of the Traditional Inventory Model

The traditional inventory model also has some challenges:

High Upfront Costs: You must spend money on products and storage before selling.

Risk of Unsold Inventory: If items don’t sell, you lose money on extra stock.

Storage Requirements: Warehouses can cost a lot, especially for many products.

Time-Consuming: Managing stock, shipping, and returns takes a lot of effort.

To succeed with this model, you need good planning to avoid risks and extra costs. If you’re prepared to invest and manage stock, this model can work well.

Print on Demand vs Traditional Inventory Model: A Side-by-Side Comparison

When choosing between print on demand and the traditional inventory model, comparing them helps. Let’s look at four key areas: cost, scalability, time efficiency, and risk.

Cost Comparison

Cost is a big factor when picking a model. With print on demand, you don’t pay upfront for stock. You only pay after a product sells, making it less risky. This is great for beginners or testing new ideas. But, each item costs more since suppliers handle everything.

The traditional inventory model needs a lot of money upfront. You buy in bulk and pay for storage. While this costs more at first, it lowers the price per item. Over time, this means bigger profits. If you’re sure about demand, this model can earn more.

Tip: Unsure about demand or short on money? Try print on demand. Want higher profits and can pay upfront? Go with the traditional model.

Scalability Comparison

Scalability is also important. Print on demand is great for growing stores. You can add new products easily without worrying about storage. The platform handles production and shipping, so you can focus on marketing. This makes it perfect for fast growth.

The traditional inventory model has limits. Growing means buying more stock and finding extra storage. Managing a bigger inventory takes time and effort. If you want to grow quickly, print on demand is simpler.

Note: Think about your goals. Want to test products or grow fast? Choose print on demand. Prefer full control over stock? Pick the traditional model.

Time Efficiency Comparison

Time matters for running a business. With print on demand, you save time by outsourcing production and shipping. You don’t pack, ship, or manage stock. This lets you focus on designing and growing your store.

The traditional inventory model takes more time. You manage stock, ship orders, and handle returns. While this gives you control over quality, it’s time-consuming. If you want to save time, print on demand is better.

Did you know? Saving time helps businesses grow faster. You can focus on customers and marketing.

Risk Management Comparison

Every business faces risks. Print on demand lowers risk because you don’t keep stock. There’s no worry about unsold items or storage costs. You can also try new products without spending much.

The traditional inventory model has more risks. Unsold items can lose you money. Storage problems like damage or theft are also concerns. While profits can be higher, careful planning is needed to avoid losses.

Pro Tip: New to e-commerce or testing a market? Start with print on demand. Have steady sales and funds? The traditional model might work better.

Choosing the Right Model for Your Business

Understanding Your Business Needs

To pick between print on demand and the traditional inventory model, think about your business needs. What products do you want to sell? If you want to offer custom or personalized items, print on demand might work best. It lets you try different products without buying in bulk.

If your customers expect high-quality items and fast delivery, the traditional inventory model could be better. This model gives you control over stock and quality but needs careful planning to avoid extra unsold items. Consider your audience, product demand, and how much flexibility your business requires.

Tip: Starting an online store with limited funds? Print on demand is a low-risk way to test ideas.

Checking Your Financial Situation

Your budget is important when choosing a model. Print on demand has low upfront costs since you pay only after a sale. This is great for beginners or those with small budgets. The traditional inventory model, however, needs more money upfront. You’ll buy stock in bulk, pay for storage, and manage inventory.

To see if you’re financially ready, look at these key metrics:

Metric | What It Means |

|---|---|

Cost of Goods Sold | The direct cost of making the products you sell. |

Gross Profit | Revenue minus COGS, showing how well your pricing works. |

Quick Ratio | Shows if you can pay short-term bills with your available money. |

Inventory Turnover | How often you sell and replace your stock over time. |

These numbers help you decide if you can handle inventory risks or prefer the flexibility of print on demand.

Thinking About Your Future Goals

Your future plans should guide your choice. Do you want fast growth or long-term stability? Print on demand is scalable, so you can add new products without worrying about storage. It’s great for testing designs or quickly expanding your product range.

If you want to grow your brand or expand into new markets, the traditional inventory model might fit better. It lets you create custom packaging and ensures products are always available, which keeps customers happy. Using trends like eco-friendly practices or AI tools can also help your business grow.

Aspect | What It Means |

|---|---|

Market Expansion Plans | Adjust stock to support new markets or product lines. |

Sustainability Goals | Cut waste and use eco-friendly methods. |

Technological Advancements | Use AI tools to improve how you manage orders and stock. |

Customer Experience Focus | Make sure products are available and ship fast to keep customers happy. |

Pro Tip: Think about where you want your business to be in five years. Pick the model that matches your goals and helps you grow.

Both print on demand and the traditional inventory model have benefits. Print on demand is great for new or small businesses. It lowers risks and helps you focus on custom products and happy customers. The traditional inventory model fits businesses with steady sales and enough money to handle stock and quality.

Think about your goals and budget before choosing. Want flexibility? Use a print on demand platform. Prefer control? Spend on tools to manage inventory. Pick the model that reduces risks and matches your plans for growth and unique designs.